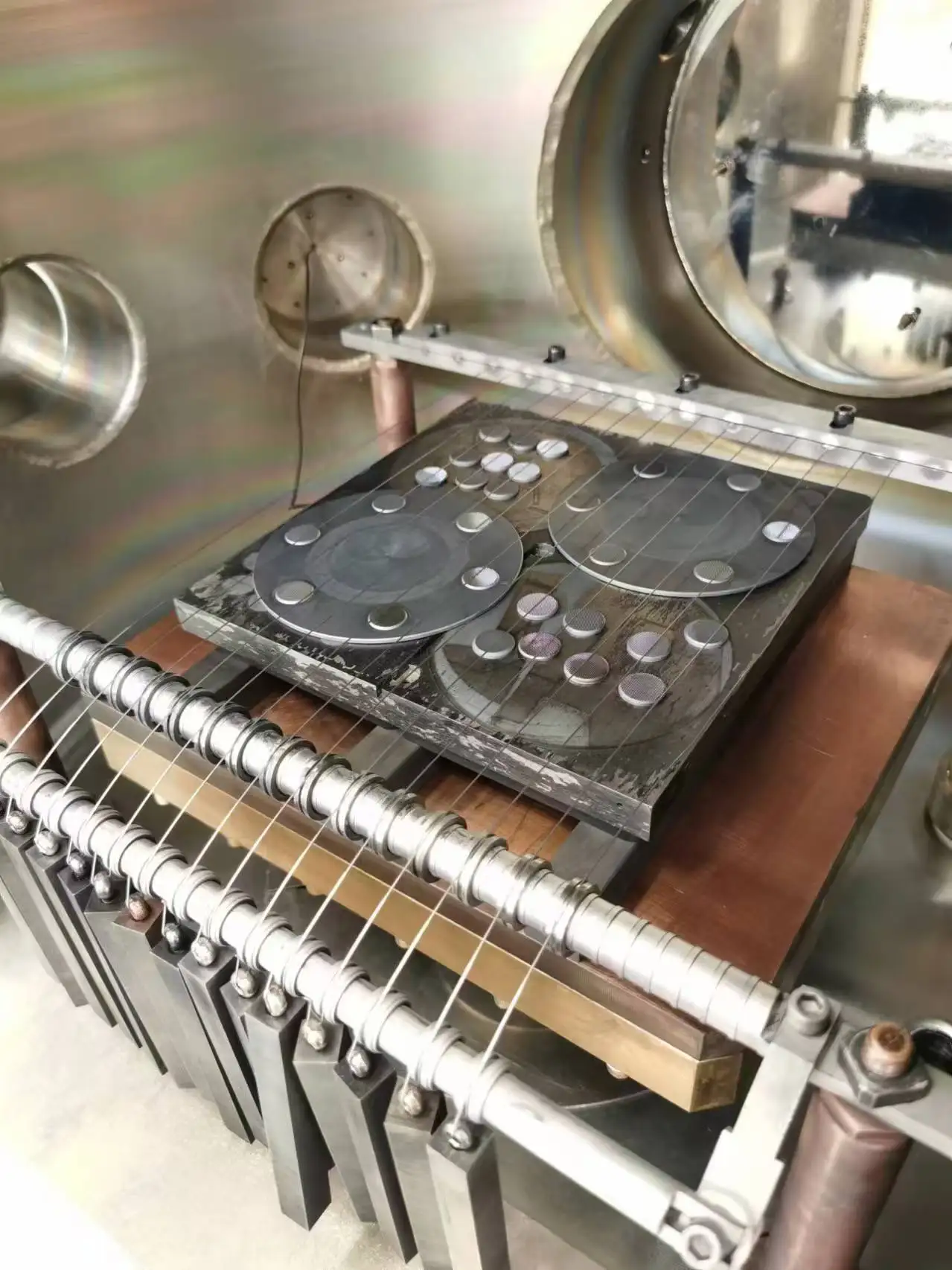

Deposition אדים כימי (hfcvd) יש יתרונות רבים כגון טכנולוגיה בוגרת וציוד פשוט. זוהי אחת השיטות הנפוצות ביותר להכנת סרטים דקים יהלומים בתעשייה. מיועד לסינתזה של ציפויים ננו-דיאמונד, סרטי יהלום cvd, ציפויים מיקרוגבישים, גרפן, ננו-צינוריות פחמן (cnts) וציפויים סרט דקים אחרים. כמו החומר הקשה ביותר בכל החומרים הידועים, יהלום יש גם מוליכות תרמית גבוהה, מודולוס אלסטי גבוה, עמידות בפני שחיקה טובה, עמידות בפני קורוזיה, מקדם חיכוך נמוך ויציבות כימית, והוא חומר מצוין לחיתוך. הציוד כולל תא תגובה, מערכת תמיכה, מערכת מים, מערכת גז ומערכת בקרה אוטומטית. הציוד קומפקטי במבנה וסביר במבנה. לאחר שנים של מחקר ופיתוח ציוד על ידי צוות המהנדס, דיונים חוזרים ונשנים, ניסויים רבים, בשילוב עם מערכת העיצוב בעזרת המחשב, נבדקו ואומתו אינספור פעמים. לציוד ביצועים מעולים ובטיחות אמינה. מוצר זה הוא מכשיר מעולה המשלב חיסכון באנרגיה, אמינות, נוחות ואינטליגנציה.

תכונות מוצר hfcvd:

מוצר זה הוא מבנה חלל נירוסטה כפול שכבה, עם מבנה קומפקטי וסביר;

מוצר זה מחולק לשני חלקים: השלב העליון והשלב התחתון. בנוסף לתמיכת תא התגובה, השלב התחתון משמש גם להסדרת שסתום גז, צינור מים ורכיבי בקרה שונים. לארגן לוחות תצוגה והתקני אספקת חשמל על הספסל כדי להגן באופן סביר;

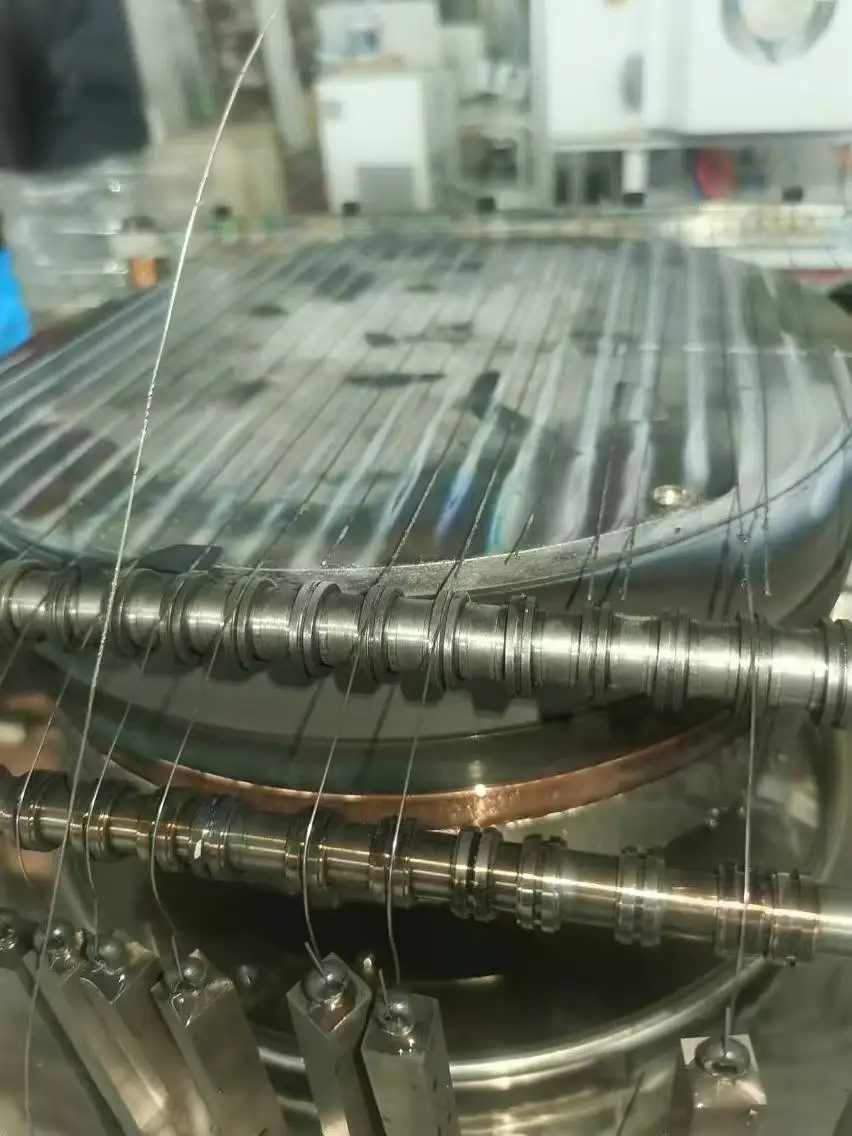

מוצר זה באופן מלא מפזר את פריסת ערוץ מי הקירור (הכיסוי העליון של החלל, השכבות העליונות והתחתונות של גוף החלל ואת הלוח התחתון, כמו גם את המכשיר אלסטי חם, וכו '). משאבות מים, צינורות מים, מד זרימה של ניטור אינטליגנטי, יריעות מים וכו 'הן כל מערכות מחזור סגור.

שילוב מעגל הגז של מוצר זה מורכב בעיקר ממערכת אספקת גז תהליך ומערכת ואקום, הפצה סבירה של צינורות גז, שימוש יעיל במרחב זמין, ניטור בזמן אמת ושליטה מדויקת בזרימת הגז והלחץ.

מוצר זה משתמש במשאבת שני שלבים, ומהירות השאיבה יציבה ב-65m 3/שעה. לחץ מלא הוואקום המוחלט המוחלט הוא 0.5 פה, ורמת ההגנה היא ip54.

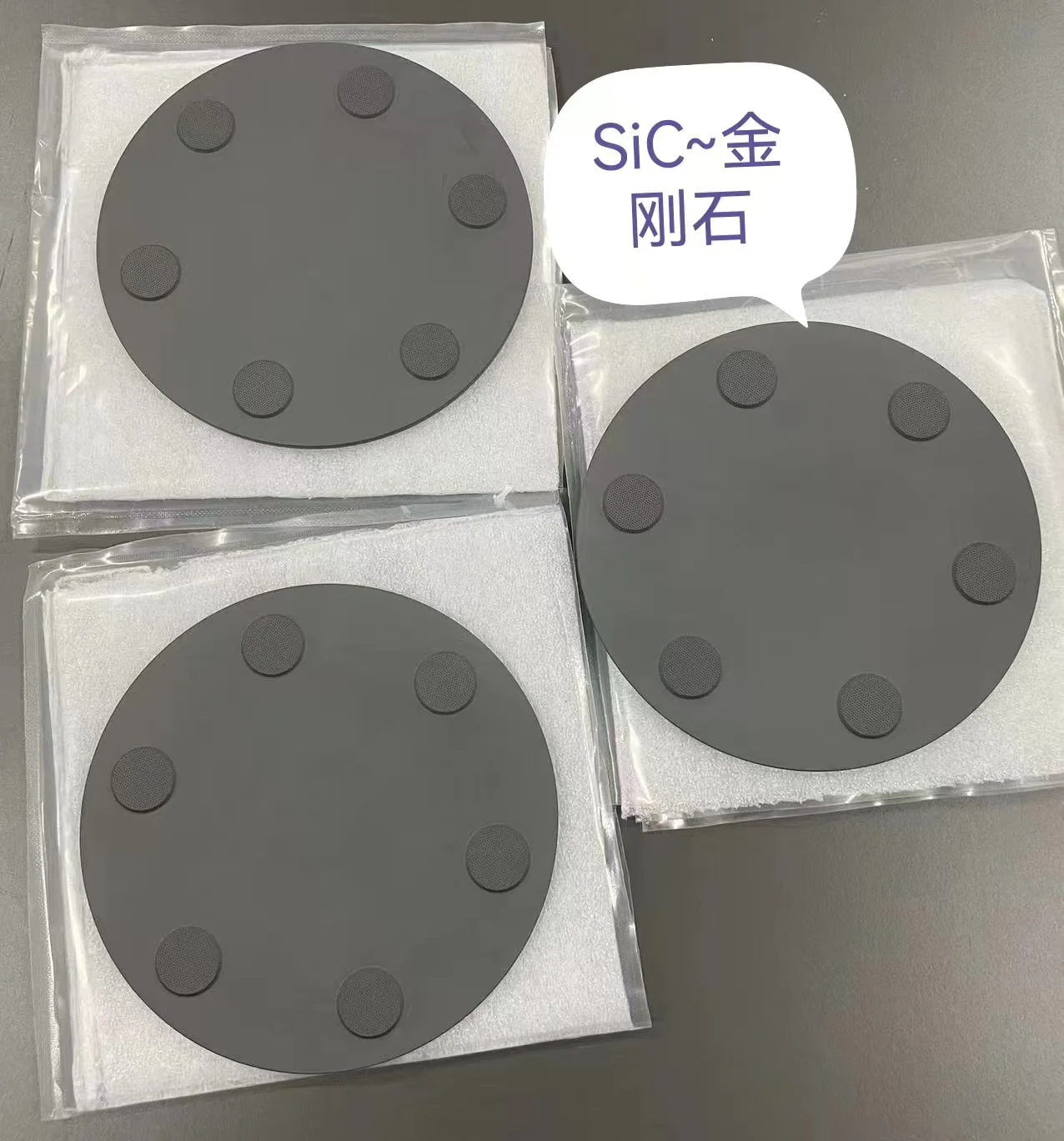

אחת השיטות הנפוצות לייצור סרטי יהלום היא טכניקת התצהיר אדי תיל חם (hfcvd), שבה תערובת גז מחומם על ידי עובר לאורך חוט ארוך, דק או טה (אומדנים100 אל 300Μמ ') מחומם עד 2400°ג. (Hfcvd) בדרך כלל רק שני גזים נדרשים: h2 ו ch4, כאשר מתאן מדולל במימן ב-1% ל-2 vol %. הלחץ הכולל בכור hfcvd משתנה בדרך כלל בין 20 mbar ל-200 mbar, כאשר קצב הזרימה הכולל תלוי בגודל והגאומטריה של הכור. (Hfcvd) בניגוד לסרטי יהלומים מיקרוגבישיים (mcd), סוג הציפוי היהלום נקרא "יהלום ננוקריסטין (ncd). Ncd מאופיינת בגודל nanocrystalline (1 ננומטר עד 50 ננומטר) ומשטח חלק מאוד, אשר שומר על קשיות של mcd ויש לו עמידות בפני חיכוך בהשוואה ל-mcd.

ציפויים אלה דורשים לעתים קרובות תוספת של גז אינרטי שלישי, אשר מסייע בהיווצרות של ncd על ידי שינוי עומס החום של גזים התא במהלך הייצור כדי לשפר את תהליך ראנוקליציה וגם להשפיע על חימום המצע. המערכת מורכבת יותר ממערכת mcd ודורשת טיפול נוסף בשליטה ובקרה של גזים הזנה. (Hfcvd) שינוי נוסף של סוג זה של כור כרוך סימום ציפוי היהלום עם בורון (mcd ו ncd) במהלך היווצרות כדי להפוך אותו מוליך. נוזל המכיל סוג של בורון (B) משמש בדרך כלל, ואדי בורון מבעבע דרך נימה חמה וציפוי יהלום על ידי גז מוביל. רמת הסמים מותאמת על ידי בחירת ריכוז בורון המתאים והתאמת הגזים שעוברים דרכו. בעת ביצוע ncd, המשימה נעשית קשה עוד יותר כי שלושה גזים מעורבים.

Hfcvd אינדיקטורים טכניים ומאפיינים:

תכונות מוצר hfcvd:

מוצר זה הוא מבנה חלל נירוסטה כפול שכבה, עם מבנה קומפקטי וסביר;

מוצר זה מחולק לשני חלקים: השלב העליון והשלב התחתון. בנוסף לתמיכת תא התגובה, השלב התחתון משמש גם להסדרת שסתום גז, צינור מים ורכיבי בקרה שונים. לארגן לוחות תצוגה והתקני אספקת חשמל על הספסל כדי להגן באופן סביר;

מוצר זה באופן מלא מפזר את פריסת ערוץ מי הקירור (הכיסוי העליון של החלל, השכבות העליונות והתחתונות של גוף החלל ואת הלוח התחתון, כמו גם את המכשיר אלסטי חם, וכו '). משאבות מים, צינורות מים, מד זרימה של ניטור אינטליגנטי, יריעות מים וכו 'הן כל מערכות מחזור סגור.

שילוב מעגל הגז של מוצר זה מורכב בעיקר ממערכת אספקת גז תהליך ומערכת ואקום, הפצה סבירה של צינורות גז, שימוש יעיל במרחב זמין, ניטור בזמן אמת ושליטה מדויקת בזרימת הגז והלחץ.

מוצר זה משתמש במשאבת שני שלבים, ומהירות השאיבה יציבה ב-65m 3/שעה. לחץ מלא הוואקום המוחלט המוחלט הוא 0.5 פה, ורמת ההגנה היא ip54.

|

Deposition אדים כימי (hfcvd) |

||

|

סוג ציוד |

CY-8904 |

CY-8906 |

|

מבנה תא ואקום |

דלת קדמית אנכית, מערכת חילוץ אוויר אחורי, קירור מים כפול |

|

|

מידות תא ואקום |

מוֹט450mmxh500mm |

מוֹט600mmxh500mm |

|

מערכת ואקום |

משאבת מולקולארית מורכבת מערכת ואקום גבוהה |

מערכת משאבת ואקום גבוהה |

|

גודל המצע |

מוֹט100 מ "מ |

מוֹט200 מ "מ או 200 מ" מ שולחן המצע מרובע (סיבוב, הרמה אופציונלי) |

|

טמפרטורת המצע |

600-1100℃ |

|

|

מקור כוח |

אספקת חשמל חם מיוחד 400a, מצב כוח נוכחי או קבוע |

אספקת חשמל חם מיוחד 800a, מצב כוח נוכחי או קבוע |

|

בקרת נתיב גז |

בקרת זרימת גז 4 כיווני |

בקרת זרימת גז 4 כיווני |

|

מצב שליטה |

בקרת מסך מגע plc |

Pc + plc + שלט מגע |

|

שטח רצפה |

מארח l1200mxw1060mmxh1900mm |

מארח l1620mxw1060mmxh1900mm |

|

כוח גס |

> 20kw |

> 43kw |

|

היקף היישום |

מכללה מחקר מדעי וניסוי, הוראה |

ייצור תעשייתי ומחקר מדעי |

|

מצוינות/תכונות מוצר |

טכנולוגיית יהלום צמצם אדים כימי חוט חם נעשה שימוש נרחב בקווי ייצור ביתיים רבים עבור כלי חיתוך יהלומים. בקרה אוטומטית לחלוטין ותהליכי ציוד יציבים וטכנולוגיות מתאימות ליישומי ציפוי ננו-יהלום גבוה והם בשימוש נרחב בייצור תעופה, תבניות מדויקות ציור תיל, אלקטרודות, וכו '. הציוד צמח סרטים בעובי של יהלומים גדולים, שמילא את הפער המקומי והשיג תועלת כלכלית משמעותית. |

|

|

שימוש עיקרי |

הוא משמש לגידול סרטים עבים ברמת מילימטר, ציפוי יהלומים ננו-קריסטלי, ציפויים של יהלומים, סרטי ניטריד סיליקון וסיליקון תחמוצת סיליקון וכו '. כדי להפקיד סרטים יהלומים על משטחים של כלי חיתוך, ברזים עובש, אלקטרודות טיפול במים, וכו'. |

|

החברה נוסדה בשנת 2005, והיא חברה המתמחה בפיתוח וייצור של ציוד מחקר טכנולוגי במעבדה. המוצרים מעורבבים, נלחץ, שרופים, לחתוך, קרקע, מלוטש, מצופה, ציוד אנליטי וחומרים נלווים. המוצרים כוללים ציוד sintering מעבדה, ציוד ציפוי וכן הלאה. כיום, היא יוצאה ל-25 מדינות ואזורים כגון מדינות המאוחדות, אירופה ודרום מזרח אסיה, והתקבלו היטב על ידי יחידות מחקר מדעיות שונות.

יש לנו צוות מחקר ופיתוח טכנולוגי בוגר, מספר הטכנאים הוא 33, לחברה 150 אנשים, יותר מ-500 מטרים רבועים של משרדים, המפעל משתרע על שטח של כ-1,500 מ "ר הממוקם באזור היי-טק. המוצרים ממוקמים בעיקר בשוק המחקר, משרת מחקר מדעי במעבדות של אוניברסיטאות ומכללות, וגם יכולים להתאים אישית מוצרים לפי הצרכים שלך.

![]()

![]()

ק. אתה יצרן או חברת סחר?

א. אנחנו יצרני ציוד מעבדה מקצועי, יש צוות עיצוב ומפעל משלהם, יש ניסיון טכני בוגר, ויכולים להבטיח את איכות המוצרים ואת המחיר האופטימלי.

ק. איך מערכת שירות לאחר המכירה של החברה שלך?

א. תקופת אחריות המוצר היא 12 חודשים, אנו יכולים לספק תחזוקה לכל החיים. יש לנו מחלקות מקצועיות לפני המכירה ולאחר מכירה מקצועיות שיכולות להגיב לך בתוך 24 שעות כדי לפתור בעיות טכניות.

ק. כמה זמן זמן המשלוח שלך? אם אני רוצה להתאים אישית את המכשיר, כמה זמן לוקח?

א. אם הסחורה במלאי, זה הוא 5-10 ימים. 2. אנו יכולים לספק שירותים מותאמים אישית עבור לקוחותינו. בדרך כלל לוקח 30-60 ימים, בהתאם למפרט של המכשיר המותאם אישית.

ק. אספקת החשמל והתקע של המדינה שלנו שונים. איך אתם פותרים את זה?

א. אנו יכולים לספק שנאי ולתקע בהתאם לדרישות המקומיות שלך על פי תקע החשמל של מדינות שונות.

ק. איך לשלם?

A.t/t, l/c, d/p וכו ', מומלץ להשתמש ערבות סחר alibaba.

ק. איך היא החבילה של סחורות? שיטות משלוח?

א. אריזת שלט יצוא רגיל תיבת עץ אריזה 2. אקספרס, אוויר, משלוח ים על פי דרישות הלקוח, למצוא את הדרך המתאימה ביותר.

שאלות נוספות, אנא צור קשר עם שירות לקוחות

כל תשלום שאתם מבצעים ב-Cooig.com מאובטח על ידי הצפנת SSL ופרוטוקולי PCI DSS קפדניים להגנה על נתונים

דרשו החזר כספי אם הזמנתכם אינה נשלחת, אובדת או מגיעה עם בעיות במוצרים